How AI is speeding up the energy transition

Herborn/Monheim, 30 April 2025

To achieve the goal of an “All Electric Society” more quickly, we need real pacesetters to implement solutions for the energy transition. The key levers in this process are digitisation, standardisation and automation. Artificial intelligence now also offers some radically new opportunities, whether it be in plant engineering or in expanding renewable energy sources. At the “Smarter E Europe” trade fair in Munich (Hall B5, Booth 310), EPLAN and Rittal will show how AI and data-driven solutions will assist companies in the future. The new RiLineX system platform from Rittal is another highlight. It speeds up the installation of power distribution solutions, resulting in time savings of up to 75%.

“Leadership in AI, combined with a great deal of industry software expertise are the most significant levers for a new growth curve and for the international competitiveness of industrial companies,” says Professor Niko Mohr, member of the Board of Management of the Friedhelm Loh Group and CEO of Rittal International and Rittal Software Systems. He added: “The future will be driven by AI. EPLAN and Rittal are pioneering and advancing industrial automation forward through AI and showing how this technology will improve mechanical, electrical, process and plant engineering tomorrow.” And it is precisely this expertise that EPLAN and Rittal want to transfer to the energy sector.

Professor Niko Mohr is a member of the Board of Management of the Friedhelm Loh Group and CEO of Rittal International and Rittal Software Systems. “The future will be driven by AI. EPLAN and Rittal are pioneering and advancing industrial automation forward through AI and showing how this technology will improve mechanical, electrical, process and plant engineering tomorrow.”

EPLAN demonstrates the potential of “engineering at the touch of a button”: AI-assisted tools allow developers to simulate a variety of different scenarios in just a few seconds, something that would previously have taken days or even weeks.

Concrete AI project case studies in engineering

At The Smarter E, these two Friedhelm Loh Group companies will provide and showcase specific solutions to show how AI will soon be helping electrical designers, engineers and planners in the energy sector improve their daily work in new and innovative ways, e.g. in expanding power grids and decentralised energy systems. EPLAN and Rittal have already put together real-life project case studies, like the AI-assisted generation of mounting plate layouts based on Microsoft Azure OpenAI Service.

EPLAN is working with Siemens on extensive end-to-end integration that will digitise and automate the entire engineering process in the future. In automation technology, for example, there are considerable efficiency gains to be had, such as a reduction in costly design and planning time.

AI-assisted tools allow developers to simulate a variety of different scenarios in just a few seconds, something that would previously have taken days or even weeks. This not only saves time but also significantly and consistently improves the quality of the outcomes. The ambition and objective is quite clear: utilise AI in current solutions to meet the specific requirements of electrical engineering companies and to automate the entire planning and design process.

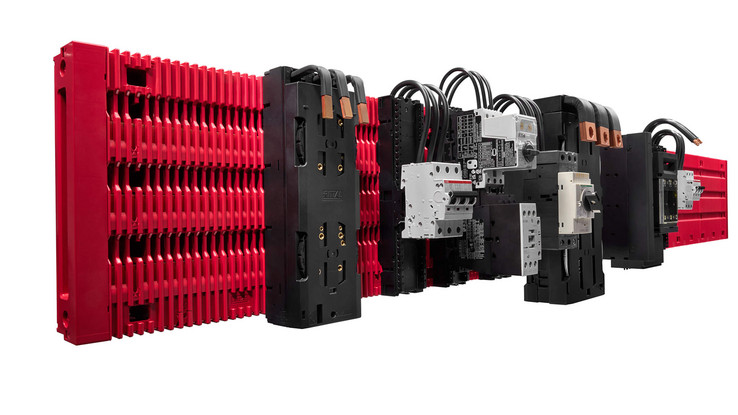

There is potential for optimisation in energy transition applications by improving power distribution system technology. The new RiLineX speeds up the production of power distribution in panel building and switchgear manufacturing by up to 75% and is suitable for AC and DC

RiLineX: The future standard in power distribution

There is also potential for optimisation in energy transition applications by improving power distribution system technology. The new RiLineX, a 60 mm busbar system platform from Rittal, speeds up the production of power distribution in panel building and switchgear manufacturing so that time savings of up to 75% can be achieved during assembly.

With a systemised platform approach, the company is driving forward international standardisation. It has launched a network of technology partners who are developing “eady for RiLineX” components that can be directly connected through a click system to the distribution board.

Partnership project for standardised charging pillars

Rittal and the software company EcoG will also show how to speed up the expansion of charging pillars and charging parks. A second-generation “Powerblock” with bayable CS Toptec outdoor enclosures is on show, combining Rittal’s system expertise with EcoG’s software and charging station components. The Powerblock thus embodies the joint project plan to standardise central, back-end infrastructure for DC charging parks and so greatly speed up the expansion of this important element of the energy transition.

Boosting expansion with engineering and collaboration

Besides speed, the energy transition also calls for efficiency and collaborative partnerships across ecosystems. Rittal and EPLAN use an industry standard “transformer station“ project. In contrast, other preconceived projects show how the concept of standardisation lays the foundation for the highly automated production of control cabinets and entire transformer stations.

Greater digitalisation, standardisation, and automation are the answers to the skilled labour shortage, while order numbers for the construction of wind and photovoltaic parks through grid connections continue to rise. At the same time, it is crucial to work together as partners across different ecosystems and to exchange data seamlessly. Thinking about value chains and the EPLAN Cloud platform makes this possible.