EPLAN documentation for a unique "flying observatory"

From shelves of files to standardised data

The SOFIA research aircraft has now been operating for 8 years, enabling close observation of space by recording infrared radiation. The complex electrical engineering of this unique telescope has so far been available only on paper and in the form of PDF documents. The team of engineers and technicians at the German SOFIA Institute (DSI) at the University of Stuttgart is now using an EPLAN solution, precisely tailored to the special requirements of fundamental astronomical research.

The view is always better from the top. This principle also applies to astronomy. If people want to explore the universe using the infrared spectrum, they'll gain little doing it from the Earth because infrared rays can't penetrate water vapour in the Earth's atmosphere.

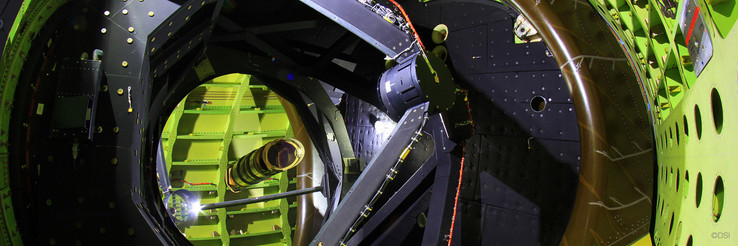

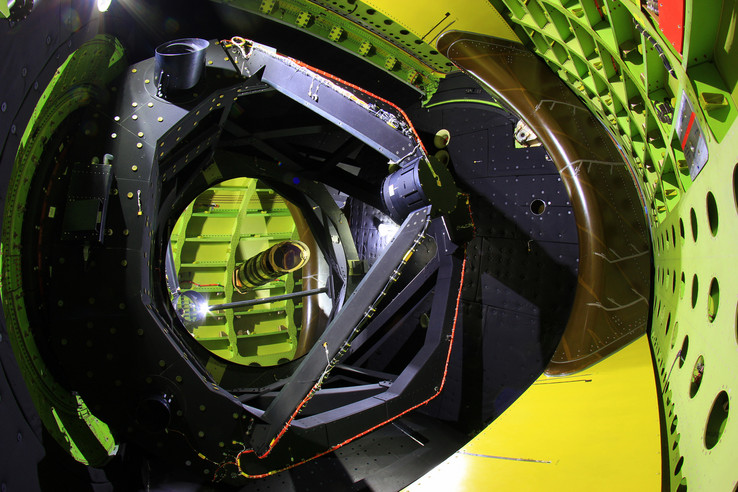

NASA and DLR (German Aerospace Center) therefore put the world's only "flying observatory" into operation in 2010. A Boeing 747 SP was fitted with a 17-ton telescope and a mirror with a 2.70 metre diameter. At altitudes of 13 to 14 kilometres, the telescope enables deep insights into, for example, the formation of stars and planetary systems.

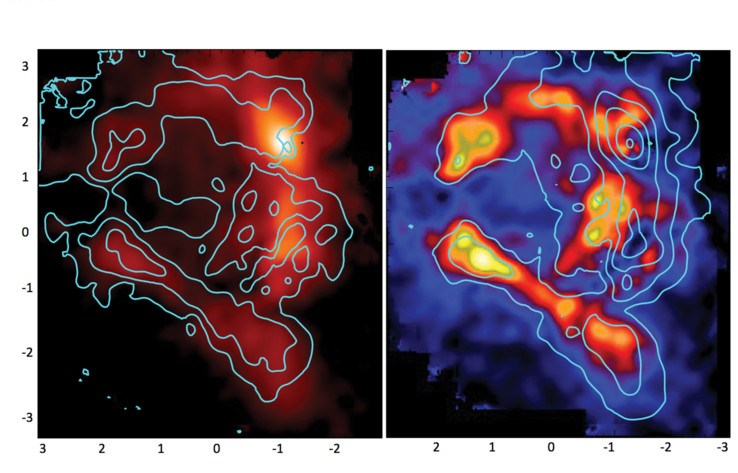

The aircraft is known as SOFIA (Stratospheric Observatory for Infrared Astronomy) and takes off several times a week from Palmdale, California for research flights. Scientists are on board and have already detected several previously unknown molecules. They are also able to study the formation of stars in detail. This is important for fundamental research because in the extremely high-energy reactions of "star birth", the fusion of atomic nuclei takes place, resulting in new, higher-value elements. Nuclear fusion transforms hydrogen and helium into new or different atoms such as carbon, oxygen and metals.

Precision job sharing

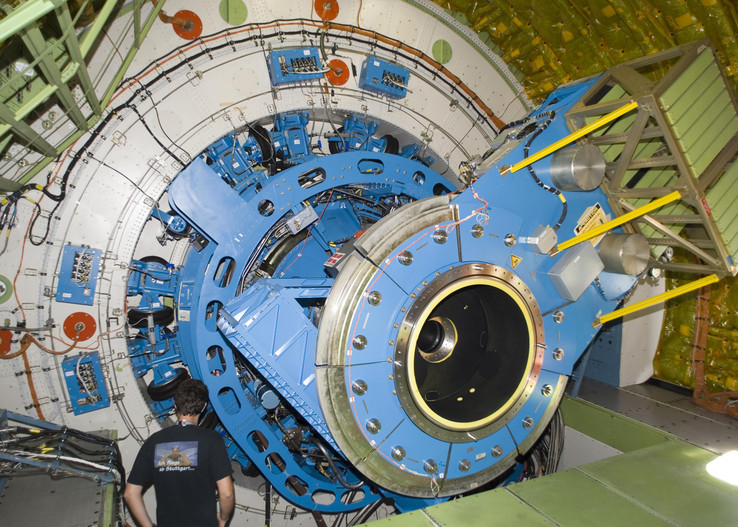

When operating SOFIA, the responsibility for tasks is stringently apportioned. NASA/USRA are responsible for flights and the aircraft. Scientific operations are carried out by the SOFIA Science Mission Operation Center (SMO) at the NASA Ames Research Center (Mountainview, California). DSI developed the telescope and is responsible for its maintenance. This job-sharing makes sense: the telescope was manufactured in Germany and its hydrostatic bearing and mirror, made of Zerodur, makes it a masterpiece of engineering in mechanical and instrument technology. It can be aligned with an accuracy of 0.2 arc seconds and is mounted with such precision that when the brakes are released, the weights of approximately 8 tons can be moved in three dimensions with just a finger. To get an idea of the precision of 0.2 arc seconds, consider that the telescope can target a 1 cent coin 16 kilometres away using a laser from a flying aircraft travelling at 800 km/h airspeed – analogous to being in a hurricane.

The majority of the approximately 50 DSI employees work at the NASA Armstrong Flight Research Center in Palmdale, where they not only carry out development and maintenance tasks, but also support activities on board and prepare new research flights. This includes adapting the telescope configuration to one of a total of six scientific instruments with different detectors for different wave ranges, each of which picks up the signals received by the telescope.

If a defect or just an irregularity occurs at the telescope, the team in Palmdale immediately goes into action. Previously, if the defect concerned the telescope's electronics, printed schematics had to be accessed which were stored in shelves of files. Simon Beckmann, who is jointly responsible for telescope electronics, says: "Developing the individual telescope systems some twenty years ago involved many specialist companies using different ECAD systems. The entire electrical documentation was therefore delivered in a variety of forms in PDFs. Keeping track when troubleshooting was then always a challenge".

Requirement for standardised, CAD-supported documentation

The above may have been a pragmatic solution then, but from a current-day perspective it was by no means a forward-looking solution: enormous effort was required for change and revision management. As SOFIA is to continue its research flights until 2034, DSI management decided to convert the entire electrical documentation to a standard system of data. This project was undertaken by Simon Beckmann, who had previously worked for several years in Palmdale as an avionics engineer and was therefore very familiar with the unique telescope setup.

A market survey at the beginning of the project gave a clear result: EPLAN best met the very special requirements although it was not strongly represented in the aerospace industry. According to Simon Beckmann, the desired basic concept was to build a DSI-specific ECAD system on the basis of three equally important pillars. The solution was therefore not off-the-shelf and was to be based on EPLAN Electric P8. The software was entirely adapted to the specific application. TPO Engineering Services GmbH in Crailsheim, Germany, was commissioned to implement the project. This involved not only converting heterogeneous design data into standard EPLAN documentation, but also incorporating general and special requirements. "TPO's employees have really done an extraordinary job", says Simon Beckmann.

A tailored system supported by three pillars

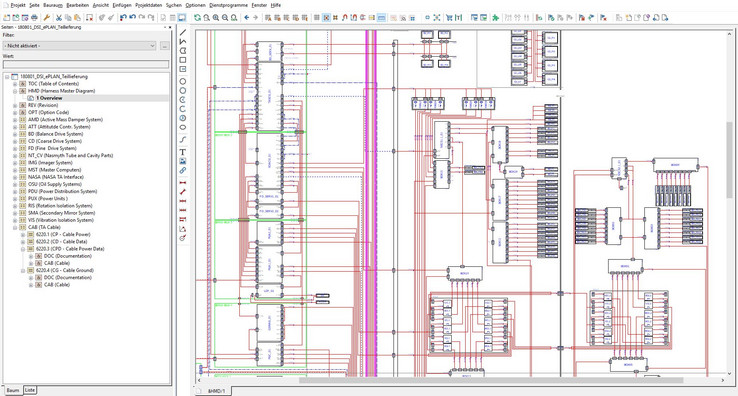

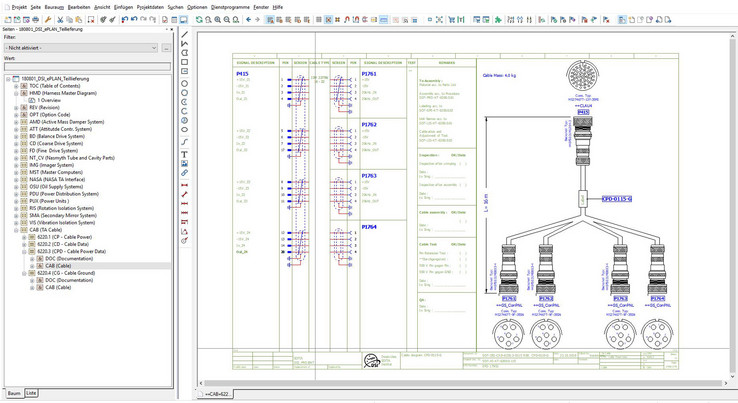

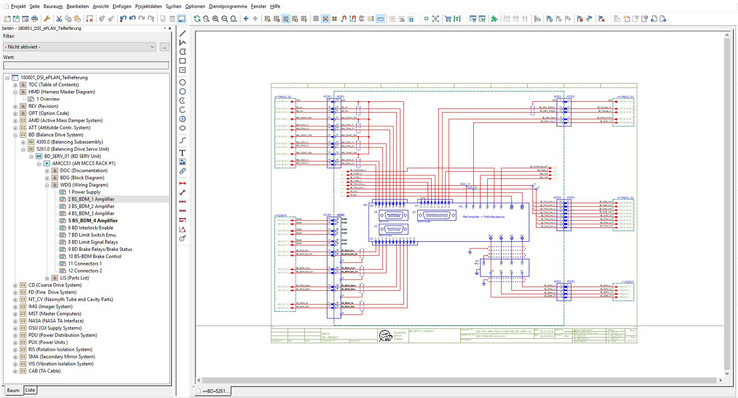

The first of the three EPLAN-based pillars is a tool, called DSI Engineering, used to modify and redesign the electrical and electronic components of the telescope system and testing equipment. The basics here include a standardised structure, the implementation of macro functions and the development of individual templates. DSI Engineering also has its own SOFIA-specific symbol library. Companies commissioned by DSI Engineering, or students working on their bachelor or master's theses, can then create cable, plug and connection lists from a single source.

ECAD-based maintenance and repair

The second pillar is the tool "DSI Maintenance and Repair". At its core is the "Harness Master Diagram" (HMD) giving an overview of the entire telescope. Simon Beckmann says: "The EPLAN schematic documents are based on the HMD and provide an efficient jump function. Despite highly complex electrical engineering and more than 2000 pages of circuit diagrams, you don't lose the overview when troubleshooting. Every DSI engineer and technician can use the EPLAN Viewer to get, at the click of a mouse, direct access to the detailed drawings, cable drawings, pin designations and data sheets of the individual components". Despite the immense wealth of detail, complexity has also been intentionally avoided. The majority of EPLAN users at DSI are not using the software daily so it needs to be intuitive to operate. Many useful functions are included. If, for example, a defective computing unit is replaced by a new unit, the EPLAN option module ensures that the schematics and associated documentation undergo updates in the background.

Mandatory proof of documentation in the aerospace industry

The third EPLAN pillar, called "Quality Assurance", is proof of documentation for the entire telescopic cabling. Simon Beckmann explains why this EPLAN option module is so important: "When the telescope was provided, no replacement units existed. We currently develop and make these in-house at DSI or have them rebuilt by manufacturers. Since the technology changes a lot, improvements of course become incorporated into any replicated components. Replacement units therefore may have the same interface to the telescope, but a completely different internal structure. The option module ensures that the DSI team can act quickly in the event of an error and that SOFIA always takes off for the next mission with the latest documentation status". This approach also serves airworthiness approvals and revision management monitoring".

The fine details: Standardising differing documentation

When the software was being installed, the SOFIA team faced the challenge of a range of different documents and schematics that had been provided by the telescope-component suppliers of the time. Simon Beckmann says: "We couldn't just transfer the documents 1:1. Each document had to be adapted and undergo some reassignment within the structure. In some cases, documents were missing or could not be clearly portrayed, so we had to check the system functions and, if unclear, our colleagues in California checked them during maintenance work".

Intensive use of EPLAN's capabilities

For Simon Beckmann, the eighteen-month project of transferring highly complex documentation into EPLAN was a major team effort into which everyone involved put a lot of passion and perseverance: "Our highly specialized requirements mean we probably use 90% of all EPLAN functions. We often needed to consult the provider and received excellent support. Some things we could solve with block properties, sometimes we got lucky and a new version was issued with the desired function. In total, more than 50 EPLAN block properties have been programmed for the project and even EPLAN employees themselves have shown great respect for the implementation. That makes us proud".

Ready for the next 15 years

With the new standardised ECAD documentation based on EPLAN, those responsible at DSI feel well prepared for future work on SOFIA's telescope and even more so for quickly troubleshooting irregularities. With the data transfer EPLAN complete, only one common and always up-to-date data status exists and DSI staff can "zoom in" on every electrotechnical detail of the telescope very quickly. The replication of individual units using EPLAN data (and thus also the modification of the documentation due to new components) has not yet been tested – simply because no component has been defective. This final practical test will however certainly occur sooner or later: SOFIA is to carry out research flights for another fifteen years, gaining insights, for example, into the birth of new stars.

SOFIA: International joint project in fundamental research

Fundamental research is usually performed as a joint project, for one thing, due to the high costs involved. This also applies to SOFIA. The operators of the "Stratospheric Observatory For Infrared Astronomy" are German Aerospace Center e.V. (DLR) and NASA. In Germany, the Federal Government, the State of Baden-Württemberg and the University of Stuttgart are providing funding for SOFIA. On the German side, scientific operations are coordinated by the German SOFIA Institute (DSI) of the University of Stuttgart, and on the American side by the Universities Space Research Association (USRA). The aircraft, a converted "Jumbo-Jet" Boeing 747 SP (a shortened version with an increased range), took off for the first time in 2010. A range of research projects is carried out on each flight and have so far led to vital findings in very different areas of astronomy.

Observatory, plane or satellite?

Large stationary observatories e.g. in the Atacama Desert, also use infrared telescopes. However, ground-based telescopes can only see to a very limited extent in the near and mid-infrared range because of water vapour in the Earth's atmosphere, and can see nothing at all into the distance due to infrared light not being able to pass through the water vapour. SOFIA therefore flies over it, at an altitude of 12–14 km. A satellite can "look" as far into space as SOFIA, but has the disadvantage that its lifetime is limited due, for example, to helium supplies being depleted to cool the cameras. The SOFIA project partners can also repeatedly re-equip the "flying observatory" with new detectors, cameras, etc. and thus set themselves new research goals. This explains the considerably longer service life of SOFIA compared to a satellite and represents an example of sustainable fundamental research.

SOFIA

SOFIA, the Stratospheric Observatory For Infrared Astronomy, is a collaborative project from the German Aerospace Center e.V. (DLR; grant number 50OK0901, 50OK1301 and 50OK1701) and the National Aeronautics and Space Administration (NASA). At the instigation of DLR, it is being carried out using funding from the German Federal Ministry of Economics and Energy under a German Bundestag decision, and from funding from the State of Baden-Württemberg and the University of Stuttgart. On the German side, scientific operations are coordinated by the German SOFIA Institute (DSI) of the University of Stuttgart, and on the American side by the Universities Space Research Association (USRA). The development of German instruments is being funded by the Max Planck Society (MPG), the German Research Foundation (DFG) and DLR.

The SOFIA research aircraft has now been operating for 8 years, enabling close observation of space by recording infrared radiation. The complex electrical engineering of this unique telescope has so far been available only on paper and in the form of PDF documents. The team of engineers and technicians at the German SOFIA Institute (DSI) at the University of Stuttgart is now using an EPLAN solution, precisely tailored to the special requirements of fundamental astronomical research.

The view is always better from the top. This principle also applies to astronomy. If people want to explore the universe using the infrared spectrum, they'll gain little doing it from the Earth because infrared rays can't penetrate water vapour in the Earth's atmosphere.

NASA and DLR (German Aerospace Center) therefore put the world's only "flying observatory" into operation in 2010. A Boeing 747 SP was fitted with a 17-ton telescope and a mirror with a 2.70 metre diameter. At altitudes of 13 to 14 kilometres, the telescope enables deep insights into, for example, the formation of stars and planetary systems.

The aircraft is known as SOFIA (Stratospheric Observatory for Infrared Astronomy) and takes off several times a week from Palmdale, California for research flights. Scientists are on board and have already detected several previously unknown molecules. They are also able to study the formation of stars in detail. This is important for fundamental research because in the extremely high-energy reactions of "star birth", the fusion of atomic nuclei takes place, resulting in new, higher-value elements. Nuclear fusion transforms hydrogen and helium into new or different atoms such as carbon, oxygen and metals.

Precision job sharing

When operating SOFIA, the responsibility for tasks is stringently apportioned. NASA/USRA are responsible for flights and the aircraft. Scientific operations are carried out by the SOFIA Science Mission Operation Center (SMO) at the NASA Ames Research Center (Mountainview, California). DSI developed the telescope and is responsible for its maintenance. This job-sharing makes sense: the telescope was manufactured in Germany and its hydrostatic bearing and mirror, made of Zerodur, makes it a masterpiece of engineering in mechanical and instrument technology. It can be aligned with an accuracy of 0.2 arc seconds and is mounted with such precision that when the brakes are released, the weights of approximately 8 tons can be moved in three dimensions with just a finger. To get an idea of the precision of 0.2 arc seconds, consider that the telescope can target a 1 cent coin 16 kilometres away using a laser from a flying aircraft travelling at 800 km/h airspeed – analogous to being in a hurricane.

The majority of the approximately 50 DSI employees work at the NASA Armstrong Flight Research Center in Palmdale, where they not only carry out development and maintenance tasks, but also support activities on board and prepare new research flights. This includes adapting the telescope configuration to one of a total of six scientific instruments with different detectors for different wave ranges, each of which picks up the signals received by the telescope.

If a defect or just an irregularity occurs at the telescope, the team in Palmdale immediately goes into action. Previously, if the defect concerned the telescope's electronics, printed schematics had to be accessed which were stored in shelves of files. Simon Beckmann, who is jointly responsible for telescope electronics, says: "Developing the individual telescope systems some twenty years ago involved many specialist companies using different ECAD systems. The entire electrical documentation was therefore delivered in a variety of forms in PDFs. Keeping track when troubleshooting was then always a challenge".

Requirement for standardised, CAD-supported documentation

The above may have been a pragmatic solution then, but from a current-day perspective it was by no means a forward-looking solution: enormous effort was required for change and revision management. As SOFIA is to continue its research flights until 2034, DSI management decided to convert the entire electrical documentation to a standard system of data. This project was undertaken by Simon Beckmann, who had previously worked for several years in Palmdale as an avionics engineer and was therefore very familiar with the unique telescope setup.

A market survey at the beginning of the project gave a clear result: EPLAN best met the very special requirements although it was not strongly represented in the aerospace industry. According to Simon Beckmann, the desired basic concept was to build a DSI-specific ECAD system on the basis of three equally important pillars. The solution was therefore not off-the-shelf and was to be based on EPLAN Electric P8. The software was entirely adapted to the specific application. TPO Engineering Services GmbH in Crailsheim, Germany, was commissioned to implement the project. This involved not only converting heterogeneous design data into standard EPLAN documentation, but also incorporating general and special requirements. "TPO's employees have really done an extraordinary job", says Simon Beckmann.

A tailored system supported by three pillars

The first of the three EPLAN-based pillars is a tool, called DSI Engineering, used to modify and redesign the electrical and electronic components of the telescope system and testing equipment. The basics here include a standardised structure, the implementation of macro functions and the development of individual templates. DSI Engineering also has its own SOFIA-specific symbol library. Companies commissioned by DSI Engineering, or students working on their bachelor or master's theses, can then create cable, plug and connection lists from a single source.

ECAD-based maintenance and repair

The second pillar is the tool "DSI Maintenance and Repair". At its core is the "Harness Master Diagram" (HMD) giving an overview of the entire telescope. Simon Beckmann says: "The EPLAN schematic documents are based on the HMD and provide an efficient jump function. Despite highly complex electrical engineering and more than 2000 pages of circuit diagrams, you don't lose the overview when troubleshooting. Every DSI engineer and technician can use the EPLAN Viewer to get, at the click of a mouse, direct access to the detailed drawings, cable drawings, pin designations and data sheets of the individual components". Despite the immense wealth of detail, complexity has also been intentionally avoided. The majority of EPLAN users at DSI are not using the software daily so it needs to be intuitive to operate. Many useful functions are included. If, for example, a defective computing unit is replaced by a new unit, the EPLAN option module ensures that the schematics and associated documentation undergo updates in the background.

Mandatory proof of documentation in the aerospace industry

The third EPLAN pillar, called "Quality Assurance", is proof of documentation for the entire telescopic cabling. Simon Beckmann explains why this EPLAN option module is so important: "When the telescope was provided, no replacement units existed. We currently develop and make these in-house at DSI or have them rebuilt by manufacturers. Since the technology changes a lot, improvements of course become incorporated into any replicated components. Replacement units therefore may have the same interface to the telescope, but a completely different internal structure. The option module ensures that the DSI team can act quickly in the event of an error and that SOFIA always takes off for the next mission with the latest documentation status". This approach also serves airworthiness approvals and revision management monitoring".

The fine details: Standardising differing documentation

When the software was being installed, the SOFIA team faced the challenge of a range of different documents and schematics that had been provided by the telescope-component suppliers of the time. Simon Beckmann says: "We couldn't just transfer the documents 1:1. Each document had to be adapted and undergo some reassignment within the structure. In some cases, documents were missing or could not be clearly portrayed, so we had to check the system functions and, if unclear, our colleagues in California checked them during maintenance work".

Intensive use of EPLAN's capabilities

For Simon Beckmann, the eighteen-month project of transferring highly complex documentation into EPLAN was a major team effort into which everyone involved put a lot of passion and perseverance: "Our highly specialized requirements mean we probably use 90% of all EPLAN functions. We often needed to consult the provider and received excellent support. Some things we could solve with block properties, sometimes we got lucky and a new version was issued with the desired function. In total, more than 50 EPLAN block properties have been programmed for the project and even EPLAN employees themselves have shown great respect for the implementation. That makes us proud".

Ready for the next 15 years

With the new standardised ECAD documentation based on EPLAN, those responsible at DSI feel well prepared for future work on SOFIA's telescope and even more so for quickly troubleshooting irregularities. With the data transfer EPLAN complete, only one common and always up-to-date data status exists and DSI staff can "zoom in" on every electrotechnical detail of the telescope very quickly. The replication of individual units using EPLAN data (and thus also the modification of the documentation due to new components) has not yet been tested – simply because no component has been defective. This final practical test will however certainly occur sooner or later: SOFIA is to carry out research flights for another fifteen years, gaining insights, for example, into the birth of new stars.

SOFIA: International joint project in fundamental research

Fundamental research is usually performed as a joint project, for one thing, due to the high costs involved. This also applies to SOFIA. The operators of the "Stratospheric Observatory For Infrared Astronomy" are German Aerospace Center e.V. (DLR) and NASA. In Germany, the Federal Government, the State of Baden-Württemberg and the University of Stuttgart are providing funding for SOFIA. On the German side, scientific operations are coordinated by the German SOFIA Institute (DSI) of the University of Stuttgart, and on the American side by the Universities Space Research Association (USRA). The aircraft, a converted "Jumbo-Jet" Boeing 747 SP (a shortened version with an increased range), took off for the first time in 2010. A range of research projects is carried out on each flight and have so far led to vital findings in very different areas of astronomy.

Observatory, plane or satellite?

Large stationary observatories e.g. in the Atacama Desert, also use infrared telescopes. However, ground-based telescopes can only see to a very limited extent in the near and mid-infrared range because of water vapour in the Earth's atmosphere, and can see nothing at all into the distance due to infrared light not being able to pass through the water vapour. SOFIA therefore flies over it, at an altitude of 12–14 km. A satellite can "look" as far into space as SOFIA, but has the disadvantage that its lifetime is limited due, for example, to helium supplies being depleted to cool the cameras. The SOFIA project partners can also repeatedly re-equip the "flying observatory" with new detectors, cameras, etc. and thus set themselves new research goals. This explains the considerably longer service life of SOFIA compared to a satellite and represents an example of sustainable fundamental research.

SOFIA

SOFIA, the Stratospheric Observatory For Infrared Astronomy, is a collaborative project from the German Aerospace Center e.V. (DLR; grant number 50OK0901, 50OK1301 and 50OK1701) and the National Aeronautics and Space Administration (NASA). At the instigation of DLR, it is being carried out using funding from the German Federal Ministry of Economics and Energy under a German Bundestag decision, and from funding from the State of Baden-Württemberg and the University of Stuttgart. On the German side, scientific operations are coordinated by the German SOFIA Institute (DSI) of the University of Stuttgart, and on the American side by the Universities Space Research Association (USRA). The development of German instruments is being funded by the Max Planck Society (MPG), the German Research Foundation (DFG) and DLR.

The DSI team is responsible for operating, developing and maintaining the unique telescope, which weighs around 17 tons.

© DSI

Simon Beckmann, next to the printed "Harness Master Diagram" (HMD), says: "Our highly specialist requirements mean we probably use 90% of all EPLAN functions".

© SOFIA

Infrared images – here of the constellation Orion – provide information about the development of star systems and the birth of new stars. The image on the left shows ambient dust temperatures. The image on the right shows the gas created by dust clouds from star formation.

© SOFIA